-

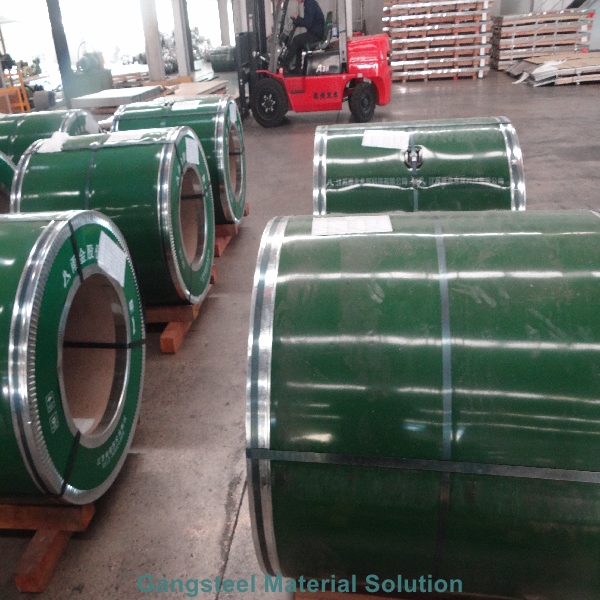

ASME SA240 316L TP316L(S31603)

We are Sa 240 316L,ASTM A 240 316L,Sa240 Grade 316L stainless steel plate supplier. We focus on high quality

-

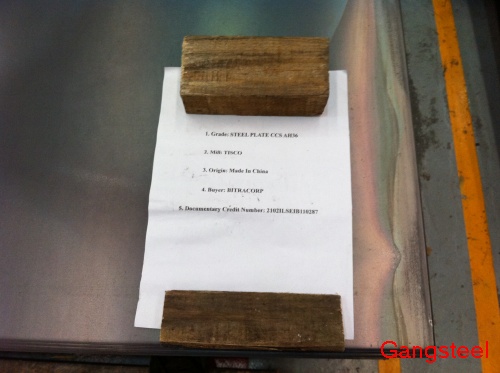

AH36,ABS AH36|AB/AH36|ABS Grade

AH36,ABS AH36|AB/AH36|ABS Grade AH36|AH36 STEEL PLATE Gangsteel is specialized in supplying ABS high strength s

-

A240 904L Stainless Steel Plate

Gangsteel provides A240 904L/SA240 904L stainless steel plate, sheet, pipe, and custom components, meeting ASTM

-

Haynes alloy 230|Nickel alloy 2

We export Haynes alloy 230|Nickel alloy 230|Alloy 230 steel plate, steel sheets and round bar, forged parts

-

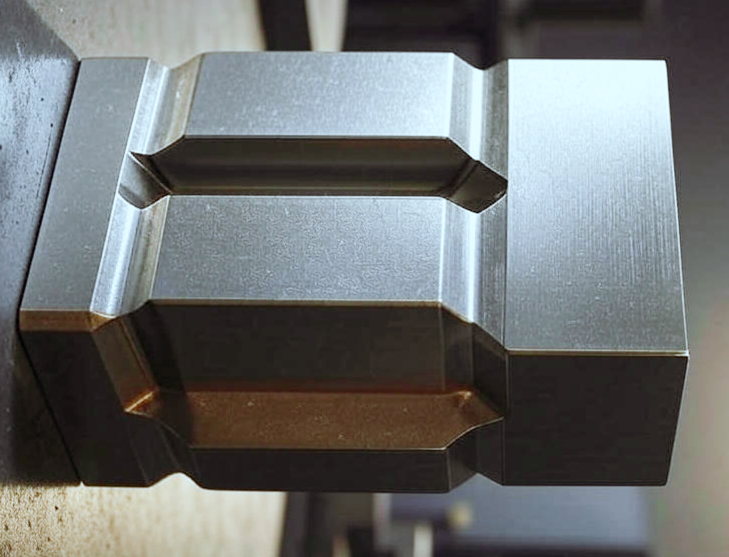

Alloy C276 Steel Plate|Alloy C2

Gangsteel Group is a leading global supplier of Hastelloy C276, also known as Alloy C276 or UNS N10276, offerin