Certificates

WYJ053-2006 1E0653

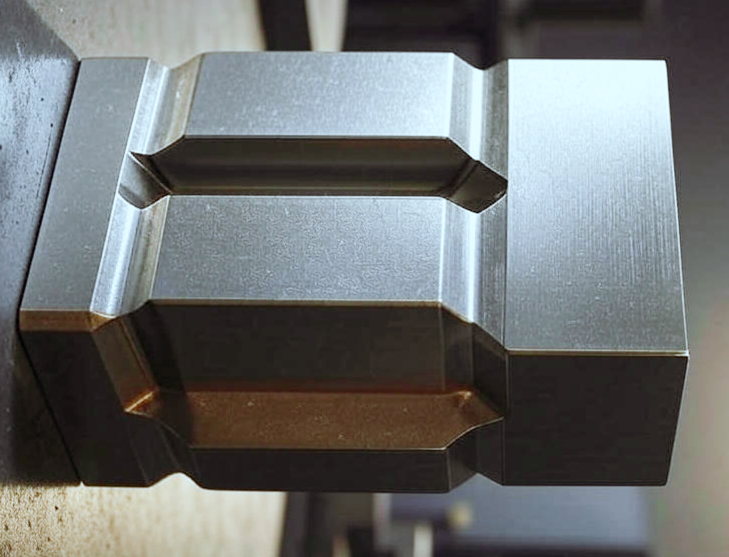

1. Suitable for:

The technology conditions apply to caterpillar engineering machinery with thickness not greater than 60 mm of adjusting quality steel plates.

2. Technical conditions

2.1 chemical composition

The chemical composition of steel (including melting analysis and product direction) should be in accordance with table 1

Table 1 Wt%

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

V

|

B

|

Al

|

Ni

|

Pb

|

Sn

|

Ti

|

Ceq

|

|

0.15

~

0.21

|

0.15

~

0.40

|

0.95

~

1.40

|

≤0.025

|

≤0.015

|

0.40

~

0.65

|

≤0.35

|

≤0.07

|

0.0005

~

0.0030

|

≥0.020

|

≤0.70

|

≤0.02

|

≤0.03

|

≤0.065

|

≤0.61

|

Note :1)Ceq=C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15

2) shall be quoted in DOB steel smelting analysis and product analysis of data, N, O, H also should also quote us, but not as a delivery terms, titanium/nitrogen than should be controlled in four or more, to ensure effective boron content.

3) products shall not exceed the chemical composition in table 1 standards range (except C are allowed to have positive and negative 0.01% of deviation, other elements to the does not allow to have the deviation).

2.2 production process:

Electric furnace-LF refining-VD vacuum deairing with continuous casting-check out clear-rolling-(shot bla)-quenching and tempering. (in principle request as soon as possible after quenching tempering).

Steel plate conditioning state delivery.

2.3 heat treatment requirements: 1) heating process of the steel plate organization completely austenitic change.

2) high temperature tempering, tempering temperature > = 585 ℃

2.4 the microstructure of the steel plate from surface to the center section microstructure is 100% tempering martensite. (in the original temper temperature on the hardness of 2 hours to tempering reduce not more than 3 HRC).

2.5 austenitic grain degrees: according to ASTM E112 carburizing method check and quote us grain degrees (> = 5 level), in no carburizing test can use GB/T6394-2002 oxidation instead. Each furnace inspection once.

2.6 mechanical properties

Inspection method according to A370 execution, the mechanical properties of the steel plate should comply with the provisions of the table 2, sample along the lateral sampling, testing and longitudinal extension performance. The yield strength press σ s0.2 detection.

Table 2

|

σs0.2 MPa

|

σb

MPa

|

δ%,50mm

|

Face shrinkage%

|

|

landscape

|

lengthways

|

landscape

|

lengthways

|

|

≥620

|

≥725~860

|

≥14

|

≥16

|

>=45

|

≥50

|

2.7 hardness: delivery the whole section steel hardness 20 ~ 30 HRC; Surface brinell hardness creasing for BR3.6 ~ 4.0 mm in diameter.

2.8 continuous casting slab low power inspection:

Casting billet should carry on the macrostructure check, erosion method should be consistent with the requirements of ASTM E381, casting billet sampling and should comply with quality E2700 chapter 1 the requirements of 7.5.2 shall. (in every batch 7.4.1 every flow take a head, tail billet transverse section).