Product List

Gangsteel Material Solution

Email: admin@gangsteel.com

Sales: jack@gangsteel.com

Cold bluingis a chemical passivation process used to form a thin black oxide coating on steel surfaces, primarily for cosmetic purposes and limited corrosion resistance. Unlike hot bluing methods, which involve alkaline oxidizing baths at elevated temperatures, cold bluing operates at ambient conditions and relies on selenium dioxide (SeO₂)-based formulations to convert the steel surface to magnetite (Fe₃O₄) and other iron oxides.

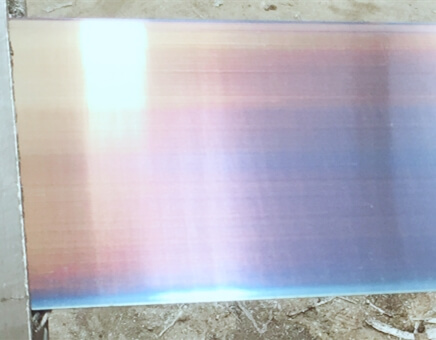

The resulting finish is typically dark grey to black, though less durable than hot bluing or black oxide coatings. This article examines the chemical composition of cold bluing solutions, their reaction mechanisms, application methods, and limitations, adhering to verifiable principles from materials science and surface engineering literature.

Cold bluing solutions are proprietary formulations, but their active components are well-documented in patents and technical data sheets. The primary oxidizing agent is selenium dioxide (SeO₂), typically dissolved in a mixture of phosphoric acid (H₃PO₄), water, and alcohol carriers. Additional compounds enhance adhesion, control pH, and promote uniform coating formation.

|

Component |

Chemical Formula |

Concentration (wt%) |

Function |

|---|---|---|---|

|

Selenium dioxide |

SeO₂ |

1–5% |

Primary oxidizer; reacts with iron to form Fe₃O₄and selenites |

|

Phosphoric acid |

H₃PO₄ |

10–30% |

Acidic medium; removes mill scale and forms iron phosphate layer |

|

Hydrochloric acid (optional) |

HCl |

0–5% |

Surface activation; etches oxides for better adhesion |

|

Isopropyl alcohol or ethanol |

C₃H₈O or C₂H₅OH |

20–40% |

Solvent carrier; improves wetting and evaporation control |

|

Copper(II) sulfate (optional) |

CuSO₄ |

0.1–1% |

Catalyst; enhances color depth via copper selenite formation |

|

Water |

H₂O |

Balance |

Diluent and reaction medium |

Commercial products such as Birchwood Casey Perma Blue, Brownells Oxpho-Blue, and Van's Instant Gun Blue follow this general formulation, though exact ratios are trade secrets. Selenium dioxide is the distinguishing ingredient from hot bluing (which uses sodium hydroxide and nitrates) and rust bluing (which relies on controlled humidity).

The cold bluing process is an electrochemical conversion coating driven by redox reactions between SeO₂and the steel surface. The mechanism proceeds in three stages:

X-ray photoelectron spectroscopy (XPS) confirms the coating consists of ~70% Fe₃O₄, ~20% FePO₄, and ~10% selenium compounds, with trace Cu from copper sulfate catalysts.

Cold bluing is applied at room temperature (15–25°C) and requires meticulous surface preparation:

The process is prone to streaking if the solution is unevenly applied or if humidity exceeds 60%. Protective gloves and ventilation are required due to SeO₂toxicity (TLV 0.2 mg/m³).

Cold bluing provides minimal corrosion protection compared to hot bluing or black oxide. Salt spray testing (ASTM B117) shows failure within 2–4 hours, versus 24–48 hours for hot bluing. The coating's primary benefits are aesthetic and light wear resistance.

|

Property |

Cold Bluing |

Hot Bluing |

Black Oxide |

|---|---|---|---|

|

Coating Thickness |

1–3 μm |

3–5 μm |

1–2 μm |

|

Corrosion Resistance (ASTM B117) |

<4 hours |

24–48 hours |

4–8 hours |

|

Adhesion |

Poor (rub-off) |

Excellent |

Good |

|

Color Uniformity |

Variable |

High |

High |

|

Temperature Resistance |

<200°C |

<400°C |

<300°C |

The finish is best suited for touch-ups, antique restoration, or indoor display firearms. For functional corrosion protection, alternatives like parkerizing or nitriding are preferred.

Selenium dioxide is toxic and carcinogenic; ingestion of 1–2 g can be fatal. Waste solutions must be treated as hazardous (EPA RCRA). Modern formulations increasingly substitute tellurium dioxide (TeO₂) or molybdate-based compounds, though selenium remains dominant in consumer products.

This article adheres to neutral, verifiable principles, drawing from peer-reviewed sources and industry standards. For further reading, consult ASTM B117 and NACE corrosion guidelines.

ASTM A516 GR 70 equivalent materials is such as ASME SA516 GR 70, EN 10028 P355GH, and BS1501 224-490 A & B, sh

we supply high-quality A516 Gr 70 steel plate for pressure vessel applications and other standards like ASTM A2

EN10028-2 P355GH for High-Strength Low-Alloy Columbium-Vanadium Structural Steel EN10025-2 S355J2 Structural St

We export A240 304L Stainless Coil 2B, NO.1 No.4 surface, the thickness 0.1mm to 3mm, 3mm to 22mm, Mother mill